Against the backdrop of the "dual carbon" goals, the steel industry, a prime example of high energy consumption and high emissions, faces unprecedented pressure to upgrade its environmental protection capabilities. Achieving ultra-low emissions while reducing transformation costs has become a pressing challenge for the industry. Tianshun Environmental Protection has successfully launched its independently developed "Fixed-Bed Dry Flue Gas Desulfurization and Denitrification System for Hot Blast Furnaces," providing an innovative solution for ultra-low emissions flue gas treatment in hot blast furnaces, rolling mill heating furnaces, and other applications for domestic steel companies.

High-temperature flue gases from blast furnaces, hot blast furnaces, and rolling mill reheating furnaces have complex composition. Traditional wet desulfurization technologies suffer from high water consumption, secondary pollution, and high operating costs. Conventional dry technologies, on the other hand, struggle to consistently meet ultra-low emission standards. National ultra-low emission standards require:

SO₂ ≤ 35mg/Nm³

NOx ≤ 50mg/Nm³

Particulate matter ≤ 10mg/Nm³

Existing technologies often struggle to simultaneously meet these three targets, and high upgrade costs pose a bottleneck hindering the green development of steel companies.

Tianshun Environmental Protection's first independently developed product—a fixed-bed dry flue gas desulfurization and denitrification system for blast furnace hot blast stoves—utilizes advanced fixed-bed technology. This technology doesn't exist in isolation; rather, it integrates big data remote control diagnostic technology, along with proprietary computational fluid dynamics (CFD) numerical simulation methods and a new granular nano-calcium-based desulfurizer. The big data remote control diagnostic technology acts like a 24/7 online "health expert," constantly monitoring the system's operating status and promptly identifying and resolving potential issues. The computational fluid dynamics (CFD) numerical simulation method acts as a precise "navigator," ensuring a more scientific and rational flow of flue gas within the system. The new granular nano-calcium-based desulfurizer is a "cleaning expert," boasting powerful adsorption and removal capabilities for pollutants.

Through the synergistic effect of these advanced technologies, the system successfully overcomes the challenge of synergistically controlling multiple pollutants in high-temperature flue gas. In actual operation, its desulfurization efficiency remains below 10 mg/Nm³, far below the national ultra-low emission standard of 35 mg/Nm³. Particulate matter emissions average 5.6 mg/Nm³, with an emission rate of 0.75 kg/h. Nitrogen oxide emissions average 17 mg/Nm³, also far below the national ultra-low emission standard of 50 mg/Nm³. A single system reduces SO₂ emissions by approximately 12.8 tons and saves approximately 80,000 tons of water annually, achieving product performance indicators that meet internationally advanced standards. More importantly, this system has reduced the cost of ultra-low emission retrofits at steel mills by over 40%, truly achieving a win-win situation for both environmental and economic benefits.

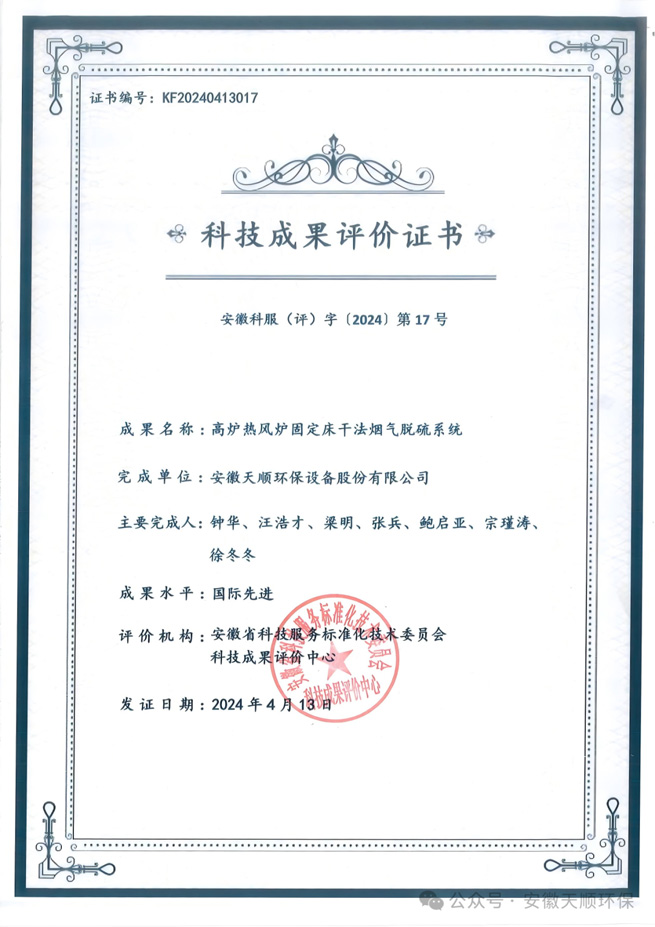

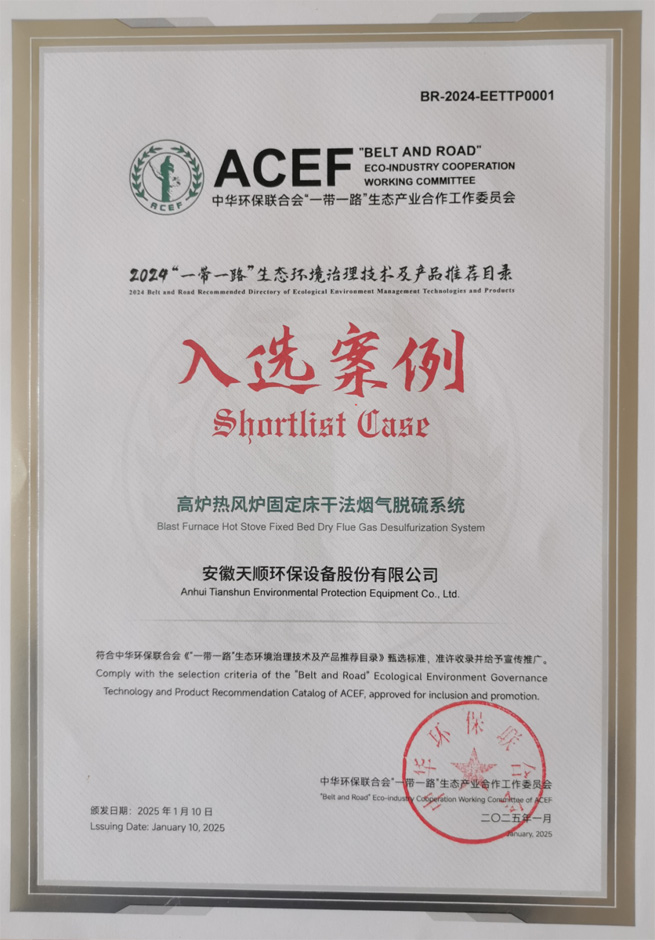

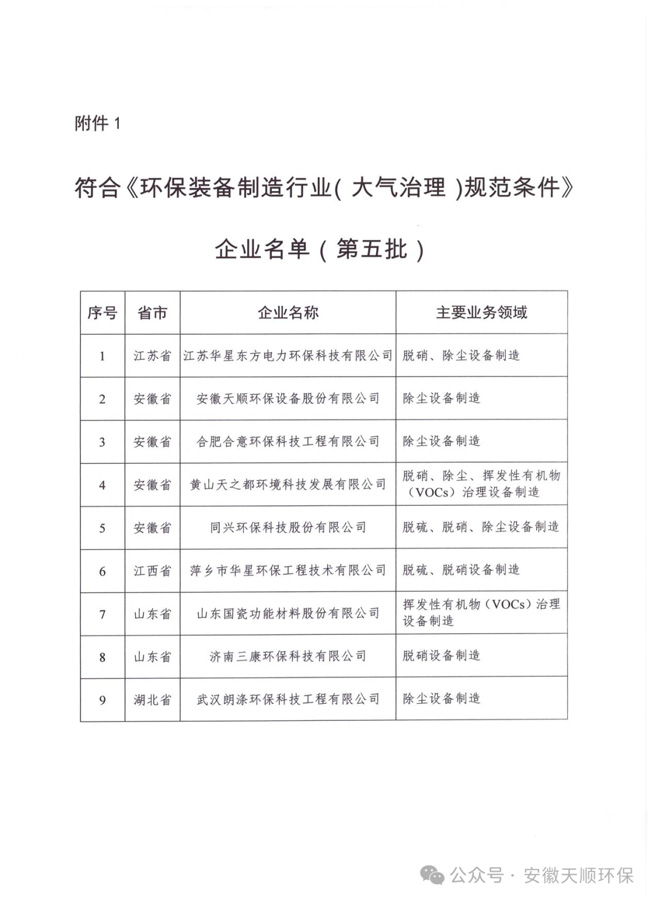

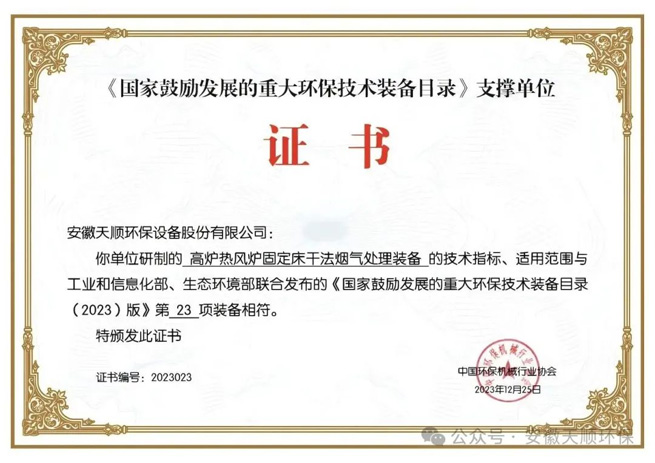

This achievement of Tianshun Environmental Protection was not achieved overnight. Behind it are years of technological accumulation and continuous R&D investment. In June 2022, the company independently completed the Anhui Provincial Key Research and Development Plan Project-Low-temperature Flue Gas Desulfurization and Denitrification and High-efficiency Bag Dust Collection Collaborative Control Technology and Equipment, and successfully passed the acceptance. This technology and equipment reduces operating resistance and improves dust removal efficiency. It has been granted 3 authorized patents and 1 new product, and related results have been industrialized. In July 2024, as the lead unit, it jointly applied with Anhui University of Technology for a provincial key project-Key Technology Research and Development and Industrial Application of Collaborative Control of Multiple Pollutants in Industrial Flue Gas, which has now entered the review stage. In addition, the company also actively participated in the formulation of two industry standards, "Technical Specifications for Ventilation and Dust Removal of Steelmaking Electric Furnace Flue Gas" and "High-temperature Bag Dust Collectors", and a number of group standards. The company's products were selected into the list of enterprises (fifth batch) that meet the "Standard Conditions for Environmental Protection Equipment Manufacturing Industry (Atmospheric Governance)" announced by the Ministry of Industry and Information Technology in 2021, and were selected into the "Catalogue of Major Environmental Protection Technologies and Equipment Encouraged for Development by the State" jointly issued by the Ministry of Industry and Information Technology and the Ministry of Ecology and Environment in 2023, demonstrating the company's technological leadership in the industry.

Selected into the list of enterprises that meet the "Standard Conditions for Environmental Protection Equipment Manufacturing Industry (Atmospheric Governance)" announced by the Ministry of Industry and Information Technology

Tianshun Environmental Protection's blast furnace hot blast stove fixed-bed dry flue gas desulfurization and denitrification system is more than just a product; it embodies Tianshun Environmental Protection's commitment to environmental protection. It provides strong support for steel companies to achieve green development and propels the steel industry towards a cleaner and more efficient future. Tianshun Environmental Protection will continue to uphold its innovative spirit and continuously improve its technology to make greater contributions to my country's environmental protection efforts. Let us all look forward to Tianshun Environmental Protection creating more miracles in the field of environmental protection and protecting our blue skies and white clouds.

Fixed-bed dry flue gas desulfurization and denitrification project for heating furnace of a steel plant in Henan

Fixed-bed dry flue gas desulfurization and denitrification project for hot blast furnaces at a steel plant in Henan Province

Tian Shun Environmental Protection's fixed-bed dry flue gas desulfurization and denitrification system for hot blast furnaces offers three key advantages: ultra-low emissions, high energy efficiency, and intelligent control. It provides an economically viable ultra-low emission solution for steel companies. Looking ahead, Tian Shun Environmental Protection will continue to deepen its commitment to environmental technology innovation, helping the steel industry enter a new era of green, low-carbon development.