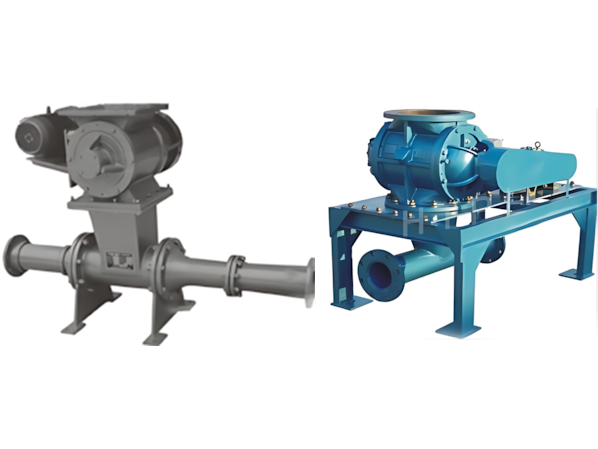

The equipment utilizes a Roots blower. Gas supply (high-pressure blowers and air compressors can also be used), and the equipment configuration is divided into two types:

A rotary feeder (also known as an electric airlock or feeder) is equipped with a jet pump. Because it uses a feeder for material supply, within a certain range... Changing the feeder's rotation speed alters its conveying capacity. This is commonly used in systems such as in-furnace calcium injection and flue gas desulfurization , depending on the flue gas flow rate. The amount of sulfur in the gas changes automatically, adjusting the delivery rate accordingly.

The LXB series material conveying pump uses low-pressure compressed air as the conveying air source , with a typical supply pressure not exceeding 0.1 MPa . Therefore, it is usually equipped with air supply equipment such as Roots blowers to form a conveying system.

The LXB series material conveying pump has a simple structure, mainly composed of a fluidized feed box, adjustable nozzles, and air supply lines. Due to its low conveying pressure, the adjustment range of conveying parameters is limited; only two settings are adjustable: the material sealing height (which is generally not adjustable depending on the setup) and the gap between the injection pipe and the conveying pipe opening. This results in poor performance for long-distance, high-height conveying.

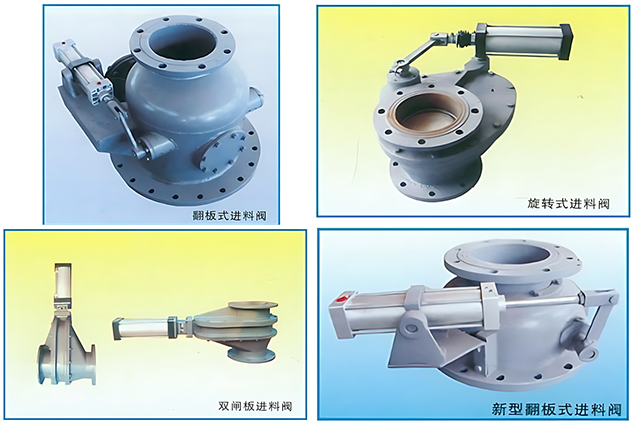

The feed valve is located at the top of the transmitter and is used to control the feed of the transmitter. Its working principle is that an external cylinder drives the shaft to rotate 90°, thereby driving the flange. When the flange is upward, the feed valve is closed; when the flange is downward, the feed valve is opened. The seal is achieved by the tight contact between the sealing ring (1) fixed on the valve body and the sealing ring (2) fixed on the flange.

The pneumatic discharge valve is located at the material outlet of the transmitter. It opens when the transmitter is conveying material and closes when the conveying process ends. During operation, the cylinder drives the valve core to rotate via a handle, thereby opening or closing the valve.

The pneumatic discharge valve is located at the material outlet of the transmitter. It opens when the transmitter is conveying material and closes when the conveying process ends. During operation, the cylinder drives the valve core to reciprocate via the piston rod, thereby opening or closing the valve.

This valve is one of the most advanced and reliable valves in the world for pneumatic ash conveying applications.

This equipment is an auxiliary device in a pneumatic conveying system. It is installed on top of the silo and is used for switching between conveying pipelines and silos. It has the advantages of convenient switching, good sealing, compact structure, and small footprint, making it an important component of the pneumatic conveying system.

The valve uses an inflatable sealing ring. When the valve is opened or closed, there is no contact between the valve core and the sealing ring. After the valve is switched, the sealing ring is inflated to achieve elastic deformation and seal.

This valve is cylinder-driven, allowing for convenient and rapid switching. It also features a position switch, and the switch signal can be sent to a PLC for remote control.

Note: To ensure reliable sealing, the inflation pressure inside the sealing ring should be 0.15-0.2 MPa higher than the pipeline pressure and must not be lower than 0.3 MPa. During media transportation and while the internal sealing ring is pressurized, it is strictly forbidden to switch the direction of media flow!

Contact With Us:

E-mail: tshb@environtechts.com

Have a Questions? Call Us:

Add:

Hanshan Industrial Park, Lintou Town, Hanshan County, Ma'anshan City, Anhui Province, China.

Please contact Tianshun for your air pollution control equipment solutions!