![]()

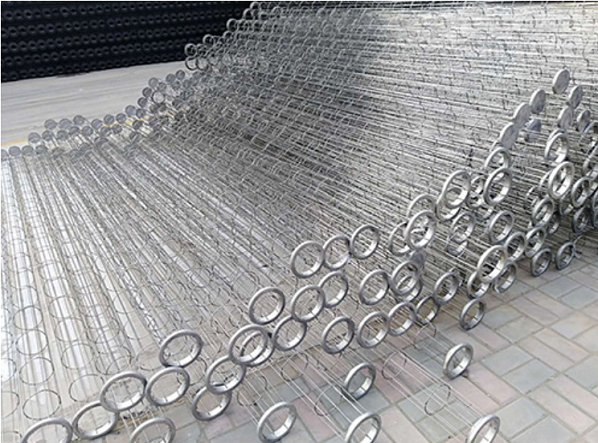

Material: Usually made of high-quality low-carbon steel Q235 or 20# wire, stainless steel wire, etc.

Shapes: Available in round, trapezoidal, oval, rhomboid, envelope, etc. Multi-section bag cages can also be made according to requirements , such as oval, round bag type, insert type, chuck type, etc.

Specifications: The diameter is generally between 80mm and 300mm, and the length can be customized according to requirements. The common length range is 100mm-8000mm.

Structure: There are various structural types such as multi-section, Venturi tube or protective short tube, bottom-discharge , plug-in, and chuck type to meet different installation and usage requirements.

Surface treatment: Common treatments include galvanizing, powder coating, and silicone spraying, which can improve the corrosion resistance and wear resistance of the bag cage, enabling it to adapt to different working environments.

Function: Primarily used to support the filter bag, preventing it from deforming or being damaged during dust removal due to airflow impact and dust adhesion. It also helps to remove and redistribute dust, optimizes the dust removal effect, and improves dust removal efficiency.

Application areas: Widely used in metallurgy, building materials, power generation, chemical industry, food, waste incinerators, coal mines, non-ferrous metal smelting and other industries.

Manufacturing standards: The support rings and longitudinal ribs must be evenly distributed and have sufficient strength and rigidity; all welds should be firmly welded, and the surface should be smooth and clean, without weld scars, unevenness and burrs; the surface must be treated with anti-corrosion to meet the usage requirements.

Contact With Us:

E-mail: tshb@environtechts.com

Have a Questions? Call Us:

Add:

Hanshan Industrial Park, Lintou Town, Hanshan County, Ma'anshan City, Anhui Province, China.

Please contact Tianshun for your air pollution control equipment solutions!