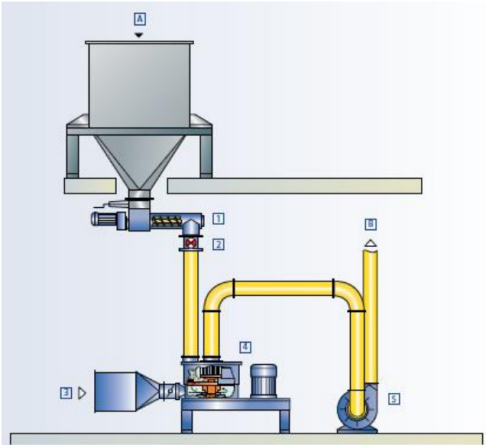

Implementation process: The ferrosilicon new-material company invested in the construction of a baking soda silo, grinder, bag-type dust collector, denitrification reactor, ammonia water evaporation system, etc.

Flue gas treatment: The flue gas from the submerged arc furnace passes through systems such as the desulfurization tower, bag-type dust collector and denitrification reactor. The SO₂, dust and nitrogen oxides in the waste gas are absorbed, transformed and decomposed.

Results and benefits: By introducing the integrated technology of dry desulfurization + bag dust collection + SCR low- temperature denitrification, the company has achieved the following benefits:

Reduction in SO₂, dust, and NOₓ emissions: The emission concentrations of SO₂, dust, and nitrogen oxides in the flue gas have been significantly reduced, meeting the requirements of environmental protection regulations.

Reduction of environmental impact: By decreasing the emissions of SO₂, dust and nitrogen oxides, the company has lessened its negative impact on the surrounding environment and enhanced its environmental-friendly image.

Compliance with regulations: The company's flue gas emissions have met the requirements of government regulations, avoiding fines and legal disputes.

Summary: The integrated technology of dry desulfurization SDS + bag dust collection + SCR low - temperature denitrification has achieved remarkable success in the treatment of submerged arc furnace flue gas. It has not only reduced the environmental impact but also enhanced the company's sustainability. This case shows that in the face of environmental pressure, the adoption of appropriate desulfurization and denitrification technologies is a crucial step towards achieving sustainable production。

It is applicable to the flue gas treatment industries with low sulfur dioxide and low nitrogen oxide content, such as the flue gas treatment of ferrosilicon submerged arc furnaces, industrial silicon submerged arc furnaces, LF refining furnaces, AOD furnaces, electric furnaces, blast furnace hot stoves, etc.

The flue gas (210±10℃) led out from the outlet of the waste heat boiler of the submerged arc furnace enters the pipeline-type desulfurization tower. The desulfurizer is ground by a grading grinder to a particle size where d90 < 20 µm, and then is conveyed into the desulfurization tower by the fan equipped with the ultra-fine powder mill. It mixes and comes into contact with the flue gas, absorbing SO₂ in the flue gas and generating sodium sulfite and sodium sulfate to achieve the purpose of desulfurization. After desulfurization, the flue gas passes through the bag-type dust collector to collect the desulfurization fly ash. Then, in the flue duct, it is mixed with ammonia gas through the ammonia-spraying grid and mixer, and then enters the denitrification reactor for denitrification. The denitrified flue gas is connected to the inlet of the main ventilator from the lower part of the denitrification reactor, and then is discharged through the chimney.

Main technical parameters: The flue gas volume of the submerged-arc furnace is 680,000 m³/h at 180℃. At the inlet of the system, the concentration of SO₂ in the flue gas is no more than 250 mg/m³, the concentration of NOₓ is no more than 500 mg/m³, and the concentration of particulate matter is no more than 5 g/m³. After environmental protection treatment, the concentration of SO₂ in the flue gas is reduced to no more than 35 mg/m³, the concentration of NOₓ is no more than 50 mg/m³, and the concentration of particulate matter is no more than 10 mg/m³.

Economic indicators: When adopting this technology, compared with traditional treatment technologies, the investment cost is saved by 50% and the operating cost is saved by 40%. In terms of environmental benefits, each furnace reduces SO₂ emissions by 395 tons, NOₓ emissions by 832 tons, and dust emissions by 9,220 tons per year.

Case 1

A new materials Co., Ltd. implemented an integrated treatment project for flue gas desulfurization, dust removal and denitrification of micro-carbon and micro-titanium high-purity ferrosilicon submerged arc furnaces. In the first phase, there are 2×40,500KVA furnaces, and in the second phase, there are 4×40,500KVA furnaces.

Implementation location: Wen County, Longnan City, Gansu Province

Implementation content: Integrated treatment of flue gas desulfurization, dust removal and denitrification

Implementation method: EPC general contracting

Case 2

A new materials Co., Ltd. carried out an integrated treatment project for flue gas desulfurization and denitrification of industrial silicon submerged arc furnaces. In the first phase, there are 2×33,000KVA furnaces, and in the second phase, there are 2×33,000KVA furnaces.

Implementation location: Zhangye City, Gansu Province

Implementation content: Integrated treatment of flue gas desulfurization and denitrification

Implementation method: EPC general contracting

Case 3

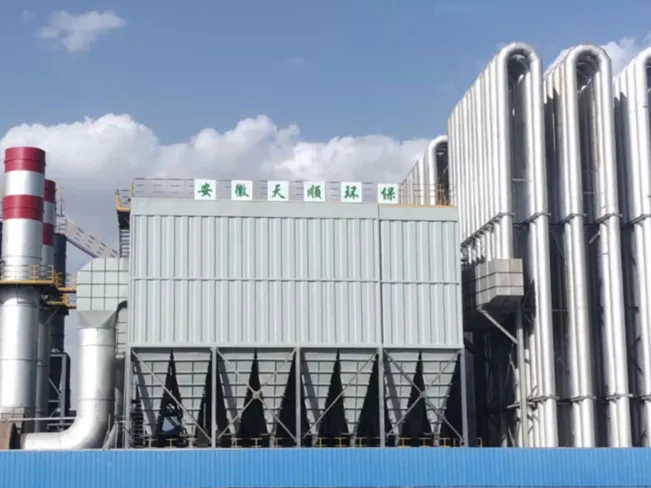

A silicon material technology Co., Ltd. implemented the dust-removal sub-project of the integrated treatment project for flue gas desulfurization, dust removal and denitrification of 12×33,000KVA industrial silicon submerged arc furnaces.

Implementation location: Baotou City, Inner Mongolia

Implementation content: The dust - removal sub - project of the integrated treatment project for flue gas desulfurization and denitrification

Implementation method: EPC general contracting

The dust collector adopts a low - pressure long - bag pulse dust collector or a positive - pressure large - bag dust collector, generally with filter bags of ϕ160X60000.

The dry flue gas desulfurization technology is the SDS sodium-based dry desulfurization process developed by Solvay in Belgium. The desulfurizer used is sodium bicarbonate (NaHCO₃). There is a thermal-activation pre-reaction in the acid-base neutralization reaction: When the freshly ground fine powder of sodium bicarbonate comes into contact with the hot flue gas, the fine sodium bicarbonate particles will rapidly transform into sodium carbonate. The sodium carbonate produced by chemical pyrolysis has a high specific surface area (the surface area can be increased by more than 10 times) and porosity. Sodium carbonate can react rapidly and effectively with acidic gases, and acids (such as hydrochloric acid, sulfur dioxide, hydrofluoric acid, etc.) are neutralized in the process.

If necessary, CFB semi-dry desulfurization or SDA semi-dry desulfurization can be adopted.

The main reaction equations are as follows:

NaHCO₃ = Na₂CO₃ + H₂O + CO₂ ------ Activation reaction (temperature 140 - 250℃)

Na₂CO₃ + SO₂ + O₂ = Na₂SO₄ + CO₂ ---- Neutralization reaction

It can remove more than 95% of SO₂; the removal rate of HCl can even reach 99%.

Selective Catalytic Reduction (SCR) denitrification technology. This method mainly uses ammonia (NH₃) as a reducing agent to selectively reduce NOₓ to N₂ and water.

The catalyst used is a low-temperature vanadium-titanium-based V₂O₅ - WO₃/TiO₂ catalyst.

The main reaction equations are as follows:

4NH₃ + 4NO + O₂ = 4N₂ + 6H₂O

4NH₃ + 4NO + O₂ = 4N₂ + 6H₂O

Contact With Us:

E-mail: tshb@environtechts.com

Have a Questions? Call Us:

Add:

Hanshan Industrial Park, Lintou Town, Hanshan County, Ma'anshan City, Anhui Province, China.

Please contact Tianshun for your air pollution control equipment solutions!